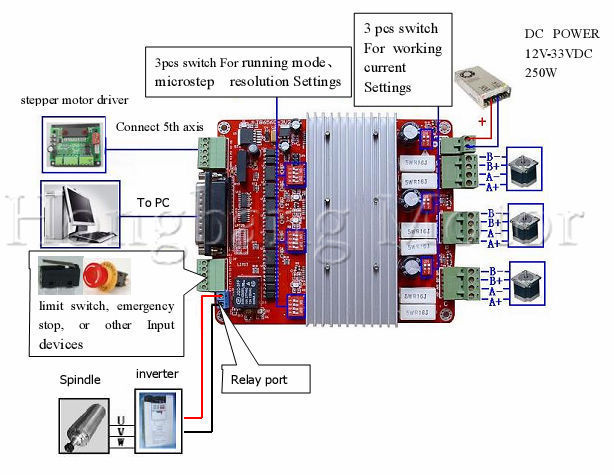

3 Axis Stepper Motor Driver Tb6560 Wiring

I have finally fixed the problem of missing steps in my Chinese made TB6560 CNC Stepper Motor Controller Keep reading for a total overview of all the associated CNC. TB6560%203A%20Driver%202-600x600.jpg' alt='3 Axis Stepper Motor Driver Tb6560 Wiring' title='3 Axis Stepper Motor Driver Tb6560 Wiring' />Hobbytronics. CNC Controller TB6. A Stepper Motor Driver Board For Mach. Backgammon Flash Game Free Download. Description. TB6. A 2. 4V. We recommend using these for a more cost effective setup for plasma, laser or small desktop CNC mill. Fixing a Chinese Made CNC Stepper Motor Driver Board TB6. Page 2 of 2 lt Go to previous Page 1 of 2 Page 2 of 2 See all Home. DIYStuff articles. Connecting the CNC Controller Board to the new Schmitt Trigger PCBNow the circuit track to tap into has been identified, we need to connect the wires of the 7. HC1. 4 Schmitt Hex Inverter Trigger board you just made. Using the following photograph for reference, CAREFULLY solder. A power 5V supply on the CNC motor driver board. A ground on the CNC motor driver board. A contact for EACH noisy signal from corresponding optical isolator outputs ie one wire for each axis. A contact for EACH pin 3 track for the Toshiba TB6. A picture is worth a thousand words, so follow this diagram carefully for reference Fig 6. Click to enlargeFig 6 CNC Controller Board modifications overall layout. Cutting the Original Copper Tracks. Transmission 0.7 Beta on this page. We have to make one cut of the original copper track per axis. Again, you are looking at the lighter colored blue material of the circuit board that is the conductive Copper, not the darker color. We now need to cut the original connection between the optical isolator output leg and the TB6. For a 4 axis board, you will need to make four very careful cuts on the circuit board tracks as shown in the photograph with a sharp blade, pocket knife or electric grinder. There is one cut to make per motor axis. In cutting the connection, you need to ensure you break the copper contact completely, not just scratch the top layer off the protective lacquer. Test the track is properly cut by testing the ends with a multimeter afterwards. University Of Detroit Mercy Summer Reading Skills Program. Careful of neighboring circuit tracksClick to EnlargeFig 7 Required circuit track cuts on the CNC Motor Controller Board. With this YOURE DONE The board should now work properly. Now Check, Check and Re Check Check and re check all components, connections and wiring before testing with the board connected to your CNC machine. Do not test with the cutter operating or near the limits of the machine table until you are certain all is working as it should

CNC Controller TB6560 3. A Stepper Motor Driver Board For Mach3. Bienvenidos en Espanol Welcome to the community maintained website of the LinuxCNC Project Notice the wiki password has changed See BasicSteps. Xloader keeps freezing while Uploading Is there something that I am missing I have tried it on both my laptopWindows 7 64 and my desktop Windows 10 64. UNIVELOP 3Axis TB6560 CNC Driver Board V2. Users Manual Univelop Comp. Tech. LLC. http 5 1. Connect board power and motor power to the board as. This is a quick guide to help with assembling the Arduino CNC Shield V3. XX. We also have a discussion forum for this board httpforum. Your CNC machine should behave very differently to what it once did The Modification Outcome A Very Satisfying Solution My CNC machine now works fantasticallyThe TB6560 motor driver accepts step and direction inputs. I use Linuxcnc on my PC. The TB6560 is a bipolar motor driver so it works with motors that have 4, or 8 wires. This was a very satisfying repair project, which is part of the reason I am so enthusiastic to share my experience with others. It is hoped that this guide makes it easier for people to modify their boards for similar results too. My modifications produced a CNC cutter with no more missed steps from my stepper motors. I also found I had gained some extra torque from the motors and that the motors also run far smoother and quieter both in axis travel and in hold. HTB1lZrgHpXXXXbKXpXXq6xXFXXX0/221908926/HTB1lZrgHpXXXXbKXpXXq6xXFXXX0.jpg' alt='3 Axis Stepper Motor Driver Tb6560 Wiring' title='3 Axis Stepper Motor Driver Tb6560 Wiring' />Credit Where Credit is Due. There is no way I could have started out this hacking project without initial assistance from the guys contributing to CNCZones forum. While these sites put me on to the the idea of what work was required, I initially found them a little confusing, Information was scattered and the original photographs were a little rough. Axis Stepper Motor Driver Tb6560 Wiring' title='3 Axis Stepper Motor Driver Tb6560 Wiring' />The soldering points unclear. Once I had the solution nutted out however, the job was easy. Summary. In the end, despite initial problems, I do not regret buying the Chinese CNC controller board at all. It saved me money, got my CNC project off the ground sufficiently and the stepping problem ended up being another great learning side project, if nothing else. The more I know about my CNC machine operation the better Anyhow, if you are having problems due to this same board design, I hope I have provided help. Best of luck and happy CNCing or 3. D printing, laser cutting, plasma cutting or plotting lt Go to previous Page 1 of 2 Page 2 of 2 See all Home. DIYStuff articles.

CNC Controller TB6560 3. A Stepper Motor Driver Board For Mach3. Bienvenidos en Espanol Welcome to the community maintained website of the LinuxCNC Project Notice the wiki password has changed See BasicSteps. Xloader keeps freezing while Uploading Is there something that I am missing I have tried it on both my laptopWindows 7 64 and my desktop Windows 10 64. UNIVELOP 3Axis TB6560 CNC Driver Board V2. Users Manual Univelop Comp. Tech. LLC. http 5 1. Connect board power and motor power to the board as. This is a quick guide to help with assembling the Arduino CNC Shield V3. XX. We also have a discussion forum for this board httpforum. Your CNC machine should behave very differently to what it once did The Modification Outcome A Very Satisfying Solution My CNC machine now works fantasticallyThe TB6560 motor driver accepts step and direction inputs. I use Linuxcnc on my PC. The TB6560 is a bipolar motor driver so it works with motors that have 4, or 8 wires. This was a very satisfying repair project, which is part of the reason I am so enthusiastic to share my experience with others. It is hoped that this guide makes it easier for people to modify their boards for similar results too. My modifications produced a CNC cutter with no more missed steps from my stepper motors. I also found I had gained some extra torque from the motors and that the motors also run far smoother and quieter both in axis travel and in hold. HTB1lZrgHpXXXXbKXpXXq6xXFXXX0/221908926/HTB1lZrgHpXXXXbKXpXXq6xXFXXX0.jpg' alt='3 Axis Stepper Motor Driver Tb6560 Wiring' title='3 Axis Stepper Motor Driver Tb6560 Wiring' />Credit Where Credit is Due. There is no way I could have started out this hacking project without initial assistance from the guys contributing to CNCZones forum. While these sites put me on to the the idea of what work was required, I initially found them a little confusing, Information was scattered and the original photographs were a little rough. Axis Stepper Motor Driver Tb6560 Wiring' title='3 Axis Stepper Motor Driver Tb6560 Wiring' />The soldering points unclear. Once I had the solution nutted out however, the job was easy. Summary. In the end, despite initial problems, I do not regret buying the Chinese CNC controller board at all. It saved me money, got my CNC project off the ground sufficiently and the stepping problem ended up being another great learning side project, if nothing else. The more I know about my CNC machine operation the better Anyhow, if you are having problems due to this same board design, I hope I have provided help. Best of luck and happy CNCing or 3. D printing, laser cutting, plasma cutting or plotting lt Go to previous Page 1 of 2 Page 2 of 2 See all Home. DIYStuff articles.